Maintenance

Pipeline repairs are not expected to be necessary during Nord Stream’s minimum operational lifespan of 50 years. Owing to the high quality of the materials involved and the conservative design of the pipelines, damage and deformation are highly unlikely. In fact, the probability of pipeline failure or leakage is as low as one damage event every 100,000 years. Nevertheless, Nord Stream is ready for any situation as part of overseeing its certified system.

When it comes to gas transportation, different international bodies regulate health, safety and environmental performance. On top of all of these is the gold standard from the Norwegian certification body Det Norske Veritas (DNV), which specialises in risk management. Nord Stream is certified to DNV’s F101 offshore pipeline standard.

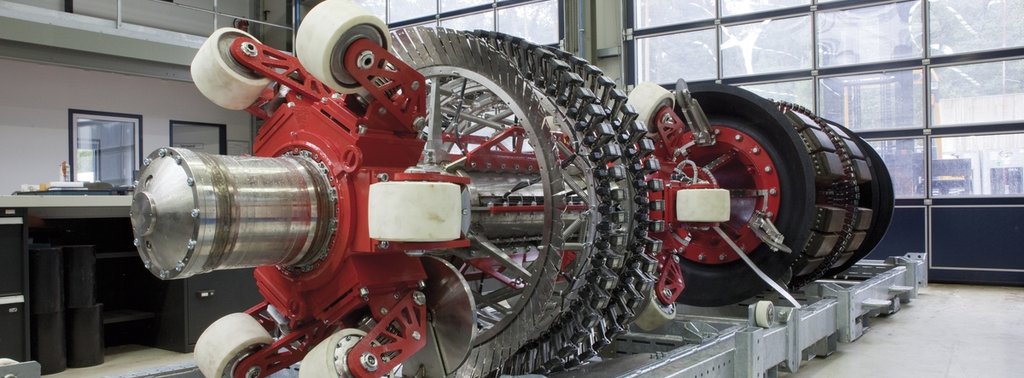

In the unlikely event that repairs are required, Nord Stream has developed an Emergency Pipeline Repair System (EPRS), is a member of the Equinor pipeline repair pool (which grants access to the equipment needed for hyperbaric welding), and has a warehouse filled with replacement pipes. The company is as prepared as it can be.

Having its operation certified yearly to the F101 DNV offshore pipeline standard, Nord Stream is committed to maintaining an ever-improving level of pipeline integrity management. The principle of dynamic integrity management is best illustrated by the frequency of internal and external pipeline surveys DNV requires Nord Stream to carry out. Initially, inspections are required annually. Each year, results are compared with those of the year before and, if nothing has changed after two or three years, the frequency of inspections could potentially be changed as long as the probability of something threatening the pipelines is minimal.

The company has created a repair strategy which models five potential scenarios. At one end of the spectrum is a minor event such as a scratch on the concrete coating. The other end concerns the worst and most unlikely event – a rupture of one of the pipelines. Each scenario requires the company to call on different resources. The final element of the offshore repair strategy involves a repair service with several contractors who would provide all the engineering, logistics, marine and construction work necessary to ensure the pipeline becomes operational again in the shortest period of time following the unlikely event of a major repair.

Of course, the maintenance and repair of the Nord Stream Pipelines does not end at the shoreline. At each landfall in Russia and Germany, contractors and staff are responsible for the regular maintenance, inspection and testing of equipment, which applies to the pipeline safety system, telecommunications system, power supply system, the fire and gas detection system, and security system, as well as the shutdown and isolation valves.

Nord Stream is committed to maintaining the highest level of reliability and safety for the long term.